|

TSWA IPAC Weigh-Labeler System

Weighing

Labeling

Bar Coding

Production Tracking and Reporting

One Software Solution That Does It All …

Imagine being able to weigh products, print bar coded labels, track thousands of items

and run detailed production reports - with a single software system. It's all possible

with the IPAC Weigh-Labeler Production Tracking System from TSW Automation Inc.

TSWA IPAC Weigh-Labeler software links your office PC with one or more Weigh-Tronix WI-130 or WPI-135

Weight Indicators for powerful results. It provides an easy-to-use, fully integrated

solution for a wide range of weighing, labeling and product tracking functions.

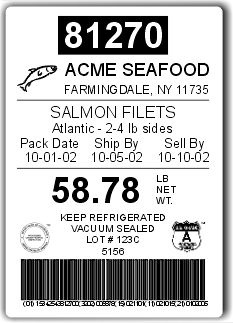

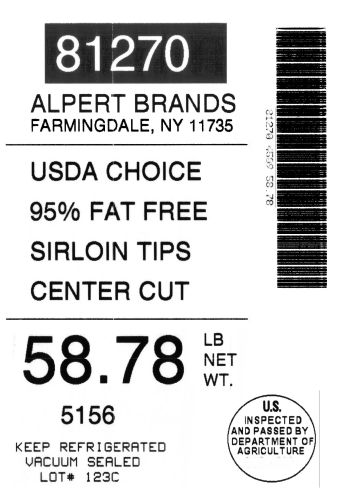

What's more, the IPAC System prints professional-looking, bar coded labels that supply

information required by the government and many vendors, including: the name of the food,

inspection legend, net weight, ingredients and the name/logo of the manufacturer, packer

or distributor. That means no more sending out packages with hand-scribbled information.

No more containers plastered with different labels. With the IPAC System, all the essential

information is neatly contained in one location … on a single label.

And this can help you:

improve your professional image

boost overall operational efficiency and productivity

comply with federal and vendor requirements

Product Features

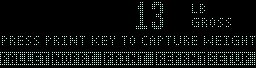

Weighing - The WI-130/WPI-135 system weighs products, calculates net weight

and accumulates the product count and weight for the pallet tag. It allows for the

printing of fixed weights, actual weights and no weight labels by product. It can

also optionally check-weigh cartons as labels are printed. Definable date descriptions

include "use thru," "pack date," "sell by," or "freeze by".

Labeling - Conveniently prints carton labels, as well as pallet labels

that are similar to the container label. The quantity will be the pallet count, and the

total product weight will be printed for the pallet.

Bar Coding - EAN 128 bar code perishable symbology prints bar code labels

with government- and vendor-required information. It includes the product code,

descriptions, spec #, size, count, net weight and a coded date (MM9999, where 9999

represents the Julian Date). The system also encodes the UPC code.

Tracking - Stores up to 5,000 product codes with up to three lines

of description. The downloadable database can contain a shelf life, a spec #, size,

piece weight, weight type flag (target or exact weight), target weight, default tare

weight, minimum weight and a maximum weight.

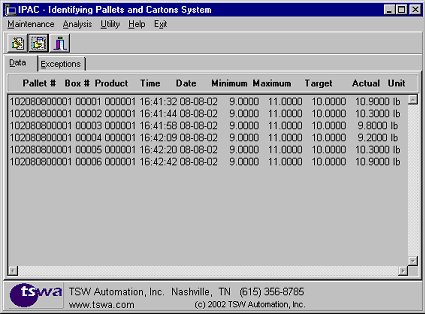

Reporting - Provides detailed transaction reports for select times,

dates, products, lot numbers, operators and stations. In most cases, sub totals grand

totals and summaries are available.

How The System Works

How The System Works

The IPAC System is designed to accumulate the weights of product containers as they are

weighed and added to a pallet. As containers are weighed, the system creates a label

with information about the container printed in text and in a UCC/EAN 128 bar code.

When a pallet of product is completed, it automatically generates a pallet label

with the number of containers and net weight.

The system provides product data to the scale station. The scale system, in turn, provides

the completed weighment data back to the PC. Then, the Windows 2000/XP compatible system

allows the stored data to be viewed in reports on a computer screen or printer. One

office PC can serve up to 16 scale stations.

Operates Without A Computer

The IPAC Weigh-Labeler System can operate normally without a PC. It can run in stand-alone

mode when your PC is down for maintenance or during unexpected power outages. Completed

weighing information will remain securely stored until the PC is reconnected.

Optional Communication Protocol

The system allows third parties, such as mainframe programmers, to directly retrieve

and delete transactions. Communication options include LAN / WAN via TCP/IP, Ethernet,

RF 802.11 (wireless), RS 232 and RS-485.

A nationwide network of local distributors

can assist with installation and service of this system.

|